AC3D’s New Off-Site 3D Concrete Printer with Telescopic Concrete Print Head

At AC3D, we’ve just upgraded our off-site printing capabilities with our Microfactory Printer featuring a telescopic vertical print head. This innovative design allows us to fabricate full-height concrete elements — such as walls and modular units — in a controlled environment and deliver them ready to install. Our telescopic mechanism system doesn’t require a high-ceiling warehouse, making it ideal for compact production spaces. Additionally, the print head is more stable, improving precision and overall print quality during printing.

Why Off-Site Matters

Off-site 3D Concrete Printing combines the speed and flexibility of additive manufacturing with the precision and consistency of factory-based production. With this setup, we can:

-

Avoid weather-related delays

-

Maintain consistent material quality

-

Reduce on-site labor and waste

-

Accelerate overall construction timelines.

Key Features of our Telescopic Concrete Print Head :

-

Telescopic vertical print head

-

Compact footprint with large print volume

-

Factory-controlled environment for high precision

-

Ideal for modular and prefab components

-

Powered by AC3D’s Codemason software

See the Printer in Action

This isn’t a prototype — it’s already operational. Check out recent printing runs and see how we’re transforming off-site construction with smarter tools and better outcomes.

Let’s Work Together

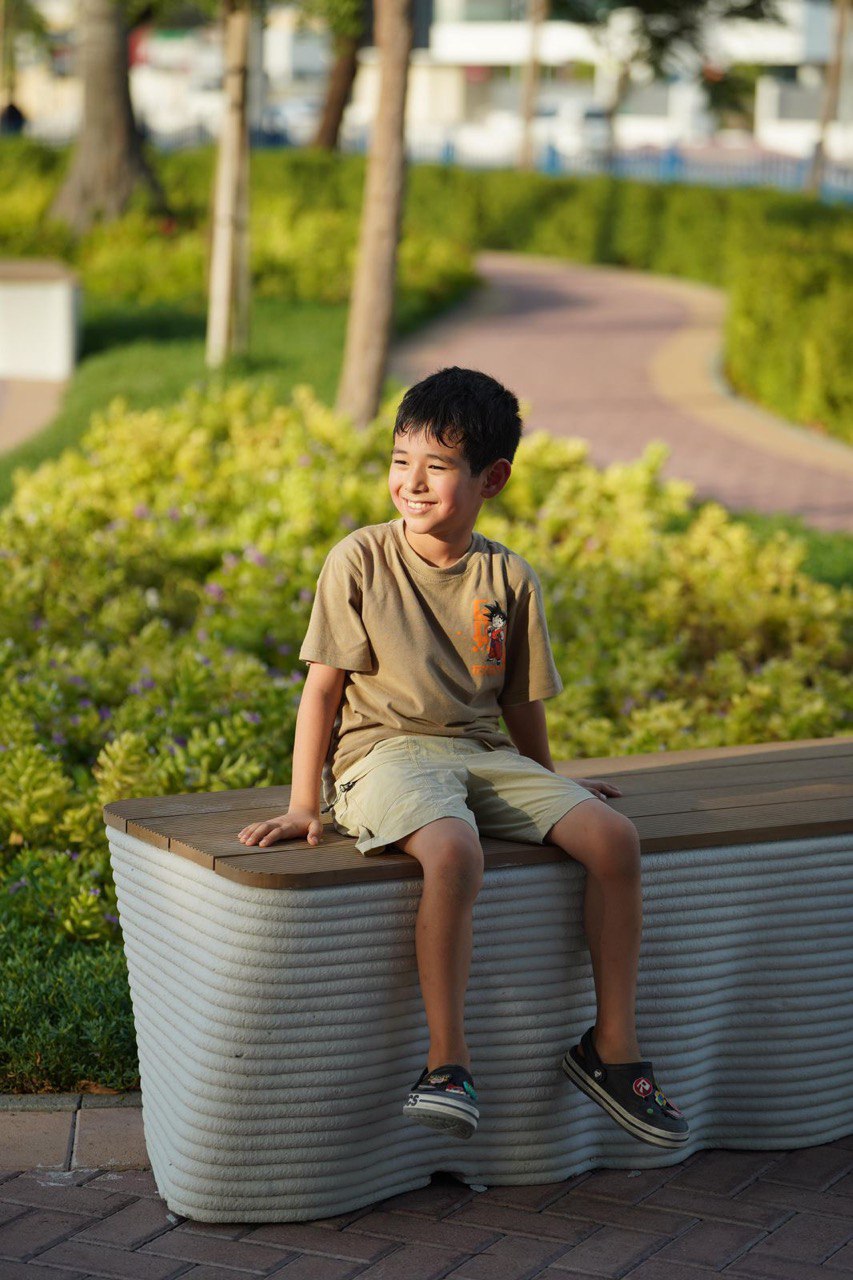

If you’re exploring ways to bring 3D concrete printing into your next project — whether modular buildings, street furniture, or test components — we’re ready to help.

Get in Touch to learn more or request a demo.